by Dot Cannon

What if you could make almost anything, as a member of a DIY maker community, in a workspace twice the size of a large house?

Can you imagine that? OK, now multiply it by three–and then some.

The result you’re imagining probably won’t come close to the reality.

Member-based DIY maker space Urban Workshop just opened its doors to the public last July, in a 5500-square-foot facility in Irvine. As of April of this year, though, they have a new Costa Mesa address–and 13,000-plus more square feet in which members and students can be creative.

“We were actually running out of room at the smaller location,” explained Urban Workshop Office Manager Melinda Murray. “We were looking around for a bigger space…and it just so happens that this building came about.”

The building in question, on Clinton Street, right near John Wayne Airport, has plenty of new additions. Above, Melinda demonstrates the lectern in the stage area…

…of Urban Workshop’s brand-new event space.

…of Urban Workshop’s brand-new event space.

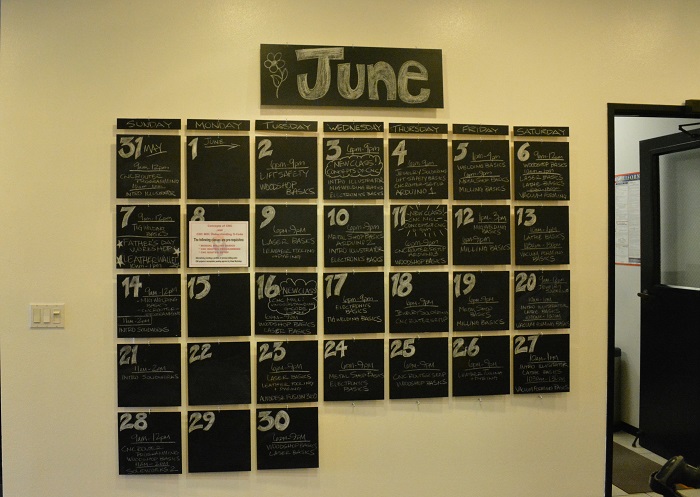

The new reception area shows a list of classes currently being offered. While Urban Workshop is member-based, their website says classes are also open to non-members.

Here’s their new conference room, with space for members to plug in their laptops at the tables along the wall.

This fabrics area, with the four-station screen printer, is one of the new additions. Urban Workshop’s latest classes include silkscreening, as well as sewing on these new industrial machines.

Urban Workshop member and instructor Henri Brownell teaches classes in Adobe Illustrator. You’ll see something familiar behind him: the laser machine, one of the most popular pieces of equipment in the facility.

Melinda said Urban Workshop has now partnered with Obrary, which has a lot of free designs available to download, personalize and cut.

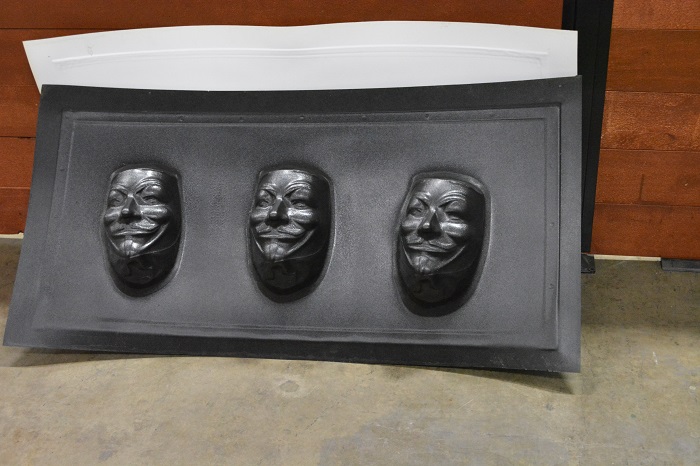

“Since we have such a large space, we actually broke out the plastics area into its own separate little unit,” Melinda said. Here, she exhibits a mask made in one of these molds.

She also said this vacuum-former can make anything from masks to some auto parts.

This CNC router isn’t new to Urban Workshop, but it’s pretty amazing. “All of these other machines in the woodshop, you can make a nice set of kitchen cabinets (by hand, and it takes a long time), Melinda said. “That machine, you program it into the software and you can spit out the whole entire cabinet out of a…sheet of plywood in nothing flat.”

But, if woodworkers prefer a more hands-on experience, there’s plenty of opportunity for that, as well.

Prefer soldering and welding? There’s also a welding area, at the very end of the facility.

But Urban Workshop’s biggest new addition…

…is this new auto shop, with five lifts.

This is the machine shop/metal shop.

And this massive piece of machinery is the CNC mill. Here, Dennis LaCrosse looks it over as part of routine daily maintenance. The CNC mill is approximately the size of a small semi-truck’s cab. Melinda says she hasn’t operated this one, but her understanding is that it can make a set of rims and pound the heads on an engine.

Of course, safety training is mandatory before anyone can use this particular machine.

“From what I’ve been hearing, it’s a pretty involved process,” Melinda said. “In order to use the mill, it’s a five-part (prerequisite class) series.”

(In fact, Urban Workshop requires safety training on any machine that “can injure you or can be damaged through improper use”, according to their website.)

The metal shop also includes bandsaws and a drill press. “Most of the machines in here are for sheet metal,” Melinda explained. “If you wanted to build a car body, the drill press would drill the holes for you.”

For Urban Workshop founder and CEO Steve Trinidade, this area represents a special area of expertise. Steve, who is president of Automotive Technology Group, Inc., is a mechanical engineer, specializing in automobile design.

“(Designing vehicles is) something I’ve done since I was a kid,” he said. “I built my first motorcycle when I was fourteen.”