by Dot Cannon

Our future could include earthquake-resistant 3-D printed houses–constructed in less than one day.

Not only that, but future medical care could involve printing cells for patients from their own healthy cells.

Oh, and some robots could be making your hamburgers, too.

Those were just three of the ideas explored, at Day Two of Automation Technology Expo–better known as ATX West. As the sign mentions, this show comprises six different areas.

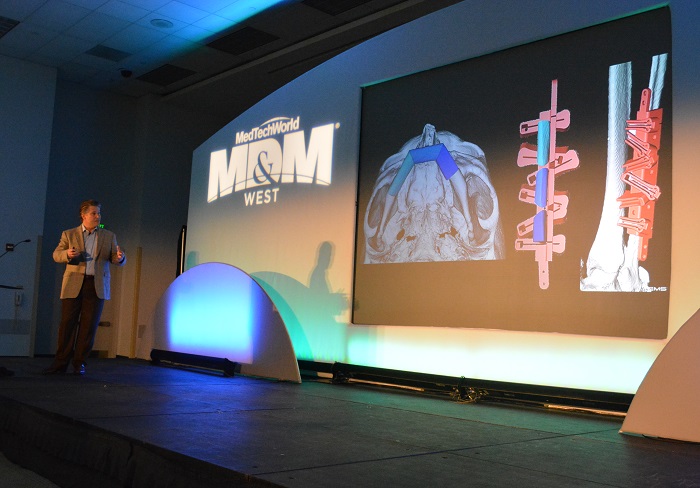

The morning started with a keynote address called “Personalizing Surgery: 3D Printing and the Digital Thread” by Andy Christensen, Vice President of Personalized Surgery & Medical Devices at 3D Systems Corporation.

“The Mayo Clinic just put on a two-day meeting, to talk about 3D printing and how it impacts medicine,” he told attendees.

Walking his audience through the ways 3D printing is revolutionizing surgery, Andy cited facial reconstruction, where both prostheses and the clamps to hold them in place are 3D printed. “The first (3D printed) implant was cleared in 2010 by the FDA,” he said.

“It’s a lot about taking personal design elements and helping fellow humans, which is a lot about what we do,” he continued.

Introducing the area of haptic-enabled design and 3D printing, Andy mentioned that scoliosis patients–usually young girls between the ages of ten and fourteen–don’t like to wear a traditional back brace. It tends to point out that the wearer has a medical issue…

…while this 3D printed one, which looks more like a fashion statement, does not.

Another medical innovation of 3D printing, Andy said, is the ability to conduct pre-surgery “rehearsals”. “They’re literally taking a patient’s image and doing a simulation,” he commented.

But the truly mind-blowing topic came last.

“Bio printing will be one of the coolest things in the next few years,” Andy told his audience. According to a slide he presented, bio printing is done by multiplying a patient’s own cells in a growth medium, then using them to print tissue that can either be used for transplants or research.

Following the keynote, the exhibits opened. Now, in contrast with International CES, ATX West had a more industrial focus. Exhibits were geared towards business and manufacturing–but still provided an intriguing look at what life in the future could become. And creativity and imagination were on display, in many forms.

Not only was this “air guitar”, by Clippard, wired to play itself…

…it was also programmed to change colors.

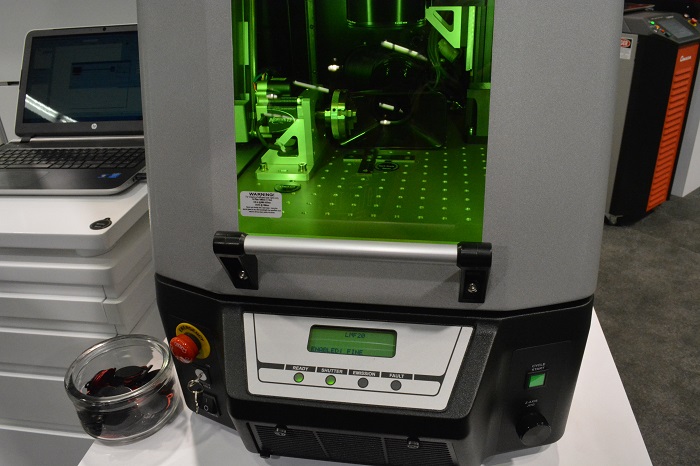

This Amada 3D printer was in the process of creating…

…these laser-etched nametags.

And this is Baxter–a collaborative robot designed by Rethink Robotics to work alongside its human counterparts.

Notice the facial change? Manager of Product Marketing and Marketing Communications Eric Foellmer said this is how the robot communicates that it hasn’t understood instructions.

Eric also said that Baxter is designed to be lightweight, so those robotic arms would feel like just brushing against another person if someone accidentally runs into one. Baxter is designed to do a variety of repetitive tasks–and he’s created by Rodney Brooks, who was one of the developers of the “Roomba” robotic vacuum!

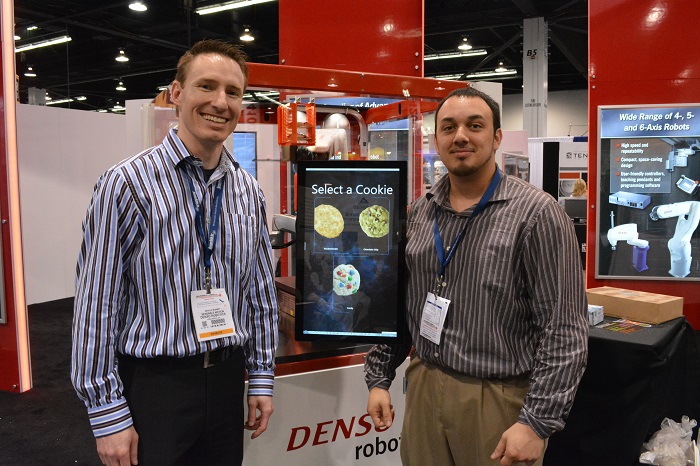

Featured in the Denso Robotics display was their latest robot, and its function…

…is to handle test tubes.

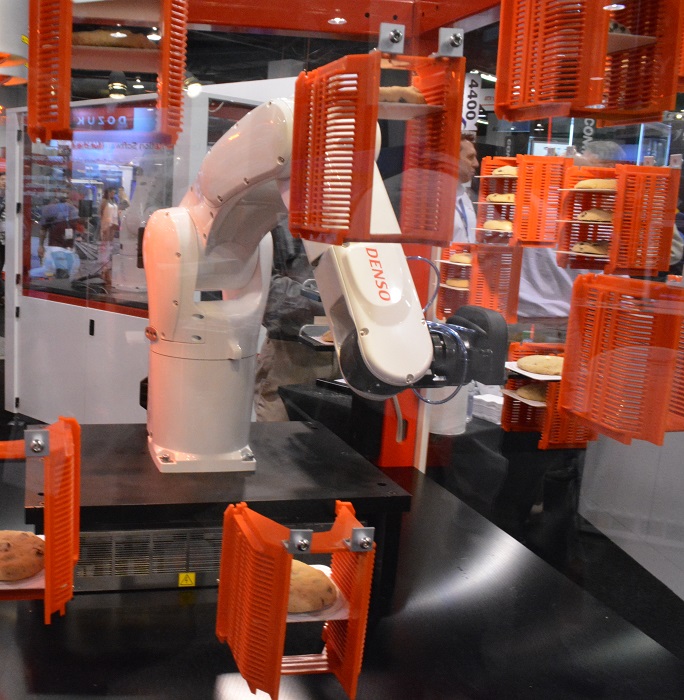

Another robot that was understandably popular was this one, created by Neville Bonwit (left). Visitors pointed to their selection on the screen…

…and it dispensed warm cookies.

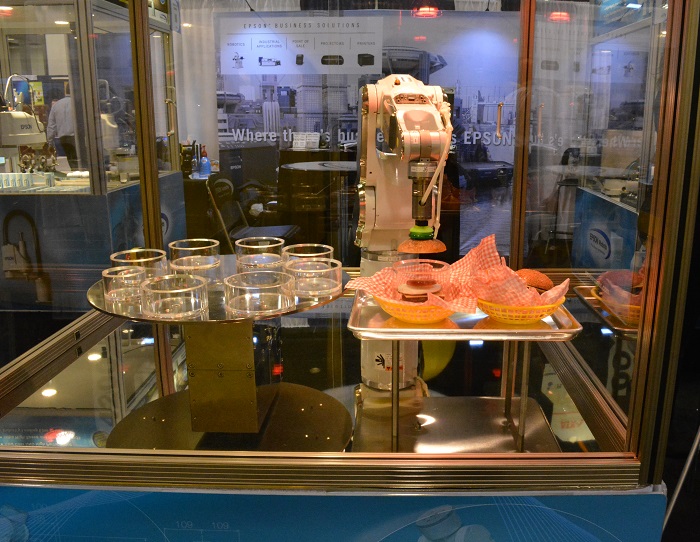

Further down in the robotics section, Epson’s newest robot was demonstrating its hamburger-construction skills.

Les Graham, Epson Western Regional Sales Manager, says this six-axle robot is designed “to draw people’s attention to the fact that you can think about robots in other areas other than automotive and electronic assembly. Think about them, maybe, grilling in your back yard one day.”

Another highlight of the day was a tour through the 3D printing displays. A very popular one was Airwolf 3D, and this is Sandy, the “Materials Girl”.

Not only is Sandy’s dress 3D printed–so are her shoes, purse and necklace!

The Forecast 3D display included both this 3D printed ukelele…

…and this bicycle, on which the handlebars, parts of the gear system and the “Forecast 3D” emblem are 3D printed.

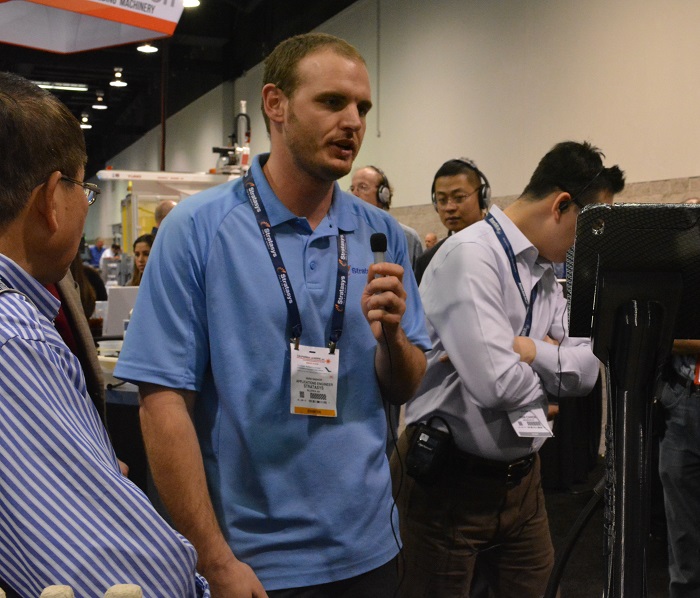

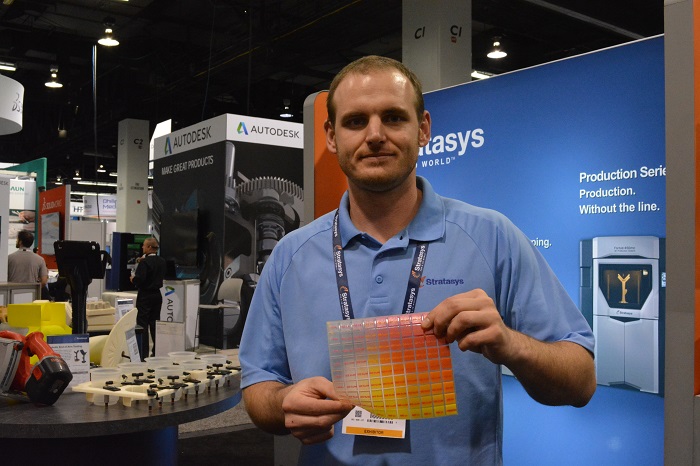

Here, Stratasys Applications Engineer Mark Bashor explains the versatility of the 3D printers this tour group is seeing…

…the plastics in which they print can range from very pliable to very firm.

The KMT exhibit was set up to remind attendees of all the materials–in addition to plastic–in which 3D printing can be done.

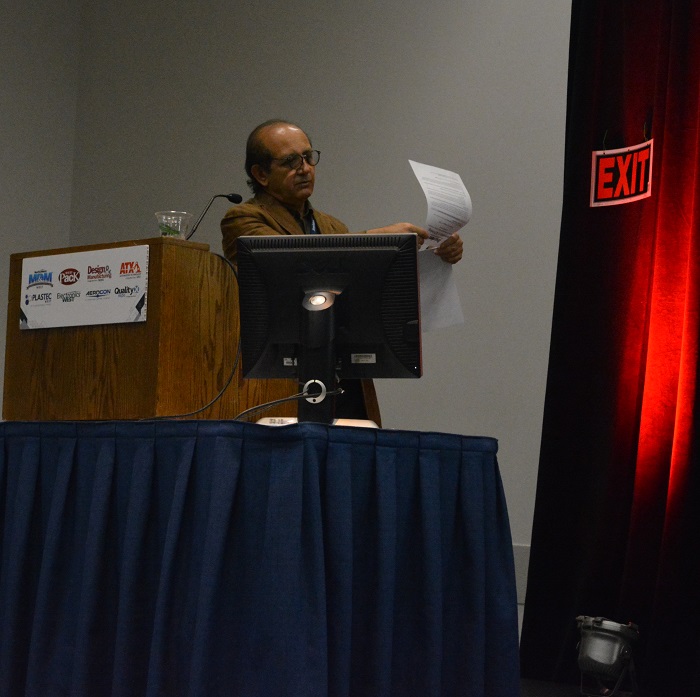

However, one of the most exciting uses of 3D printing came at the end of the day. During the closing presentation on “Enabling Factors in the 3D Printing Revolution”, USC’s Director of the Center for Rapid Automated Fabrication Technologies, Berok Khoshnevis, applied it to construction of new homes.

“You can build a custom-designed home onsite in about twenty hours,” he said, just before showing a video of concrete being used as the printing material. “Concrete reaches its maturity in twenty-eight days. This is very fresh concrete. And yet look at the strength of it.”

And in regions that are prone to earthquakes? Berok used a sheet of paper to demonstrate the principle of curved contours, which he said give durability to such structures.

“If you bend the paper a tiny bit, see how strong it becomes,” he said.

Berok also discussed a completely new area in which he was working with NASA to create 3D printed dwellings: on Mars.

“They’re going to make full demonstrations,” he said of the Kennedy and Johnson Space Centers. “We melt the soil much like flowing lava and then we build with molten soil. There’s a lot of sulfur on Mars.”

This year’s ATX West ran from Tuesday, February 10th through Thursday, February 12th, at Anaheim Convention Center. More information is available here.

Couldn’t make it this time? According to a sign near the exit of this year’s Automation Technology Expo, dates are already planned for next year: February 9th through 11th, 2016!